-

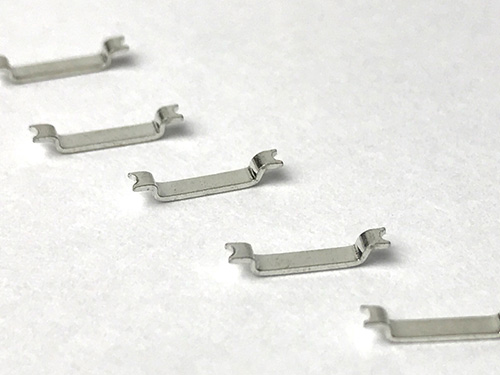

Jumper

Jumper

Jumper wire is stamping parts, hardware stamping parts hardness testing using rockwell hardness teste...

-

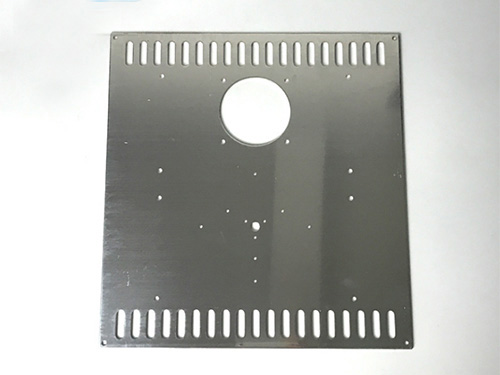

Chandelier housing

Chandelier housing

The shell of pendant lamp is a stamping part. The stamping part is a method of forming and processing...

-

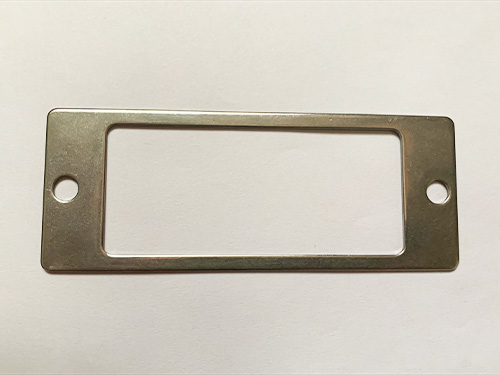

Stainless steel instrument hoop

Stainless steel instrument hoop

Stainless steel instrument hoop is stamping piece, stamping piece is by the press and die on the plat...

-

Stainless steel stamping parts

Stainless steel stamping parts

Stainless steel stamping parts are made of stainless steel material processing products, stainless st...

-

LED screen frame

LED screen frame

The frame of LED screen is a stamping part. The stamping part is a method of forming and processing p...

Causes of wrinkling of stamping parts

Jul 24

2019

In the actual operation process of many workshops, it is found that the die of stamping and drawing parts is easy to be pulled. How can we solve this problem?

Wrinkling refers to the surface roughness and uneven edges of the workpiece during the process of drawing, which will seriously affect the subsequent work. Wrinkling of stretch piece is the problem we should be concerned about, what will cause wrinkling of stretch piece, how to prevent, find out these reasons and methods, can ensure our normal operation, the product can also be guaranteed.

One, by forming the workpiece raw materials, through the study of the surface treatment of raw materials, such as raw materials for phosphating, coating or other surface treatment, cause the forming material surface to form a layer of metal mould, can greatly reduce or eliminate artifacts strain, this approach tends to the high cost, and need to add additional production equipment and increase the production process, although this method sometimes some effect, but seldom used in practical production.

Two, between the workpiece and the mold, between the mold and the forming material to add a layer of PVC film, sometimes can also solve the problem of the workpiece. For the production line through the mechanism can achieve continuous supply of film, and for the periodic production of stamping equipment, each production of a piece of workpiece needs to add a film, affecting the production efficiency, this method is generally high cost, but also will produce a large number of waste, for small batch of large workpiece production using this method is desirable.

In some cases where the forming load is very small, it is sometimes possible to solve the problem by adding lubricating oil or lubricating oil with EP additive.

Three, the mold side by changing the mold convex, concave die material or on the mold convex, concave die surface treatment or selection of appropriate mold material, so that the material to be drawn and convex, concave die such contact properties change. Practice has proved that this is an economical and effective method to solve the problem of strain injury.