-

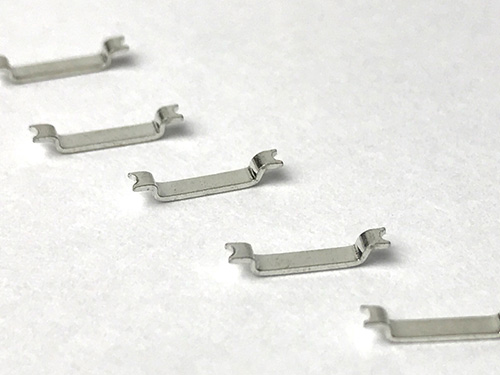

Jumper

Jumper

Jumper wire is stamping parts, hardware stamping parts hardness testing using rockwell hardness teste...

-

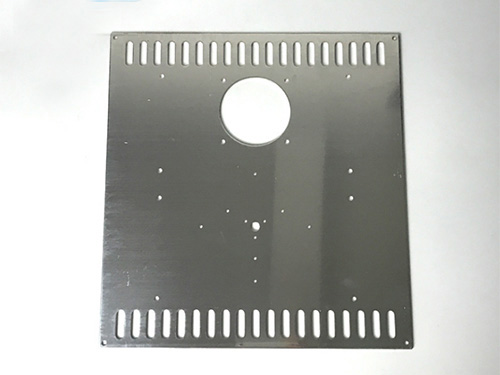

Chandelier housing

Chandelier housing

The shell of pendant lamp is a stamping part. The stamping part is a method of forming and processing...

-

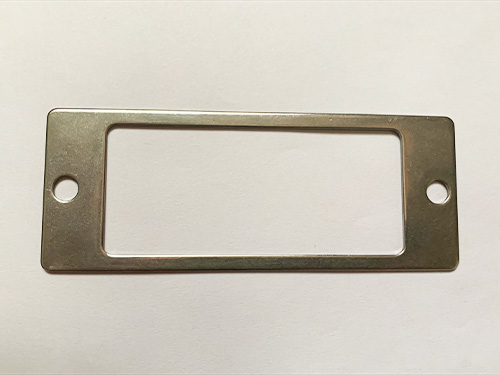

Stainless steel instrument hoop

Stainless steel instrument hoop

Stainless steel instrument hoop is stamping piece, stamping piece is by the press and die on the plat...

-

Stainless steel stamping parts

Stainless steel stamping parts

Stainless steel stamping parts are made of stainless steel material processing products, stainless st...

-

LED screen frame

LED screen frame

The frame of LED screen is a stamping part. The stamping part is a method of forming and processing p...

The wrinkling reason and maintenance measure of stretch piece

Jul 24

2019

The wrinkling of the drawing piece refers to the work piece in the process of drawing, its surface is rough and uneven, the edge is too thick, which will seriously affect the subsequent work. Wrinkling of stretch piece is the problem we should be concerned about, what will cause wrinkling of stretch piece, how to prevent, find out these reasons and methods, can ensure our normal operation, the product can also be guaranteed.

There are many reasons for stretching pieces to wrinkle, mainly have the following aspects: the stretch of the blank that the thickness of the plate is not enough, can withstand the pressure is naturally small, in the process of stretching is very easy to wrinkle; The tensile coefficient is small. If the corresponding tensile coefficient is not selected according to the texture of each blank, the deformation degree will be difficult to control. If the control is not good, the deformation will occur. The blank holder ring has been seriously damaged, so it cannot give the same pressure to the blank, resulting in uneven compression capacity and wrinkling.

In the face of these wrinkling causes, we take preventive measures. The thickness of the stretched blank should be relatively thick, so that it can withstand the relative pressure during the stretching process, and is not easy to change and wrinkle. The deformation degree can be easily controlled by selecting the tensile coefficient corresponding to the blank texture. The holder needs to be changed or repaired frequently so that the blank is subjected to the same pressure and is not prone to wrinkling.

The maintenance and maintenance of the drawing machine can not be ignored:

1. Before the installation and use of the drawing parts, please check carefully to clear the dirt and eliminate the bad factors, and check carefully whether the guide sleeve of the drawing parts and the lubrication degree of the mold are normal or not.

2, partition time on the rotary table of the press and mold installation base carefully check, ensure the up and down of the coaxiality of the rotary table.

3. Install the concave and convex molds on the rotary table in strict accordance with the installation procedure of the molds. Make sure that their pulling parts are in the same direction.

4, once found that the convex and concave die edge of tensile parts wear, stop using, and timely change the edge, the old edge for grinding, will rapidly expand the serious impact on the wear of the mold, thus reducing product quality and shorten the life of the mold.

5. Later, we would like to remind everyone about our working attitude. We should be careful and patient.