-

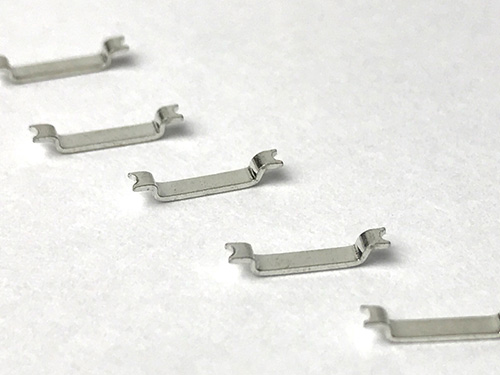

Jumper

Jumper

Jumper wire is stamping parts, hardware stamping parts hardness testing using rockwell hardness teste...

-

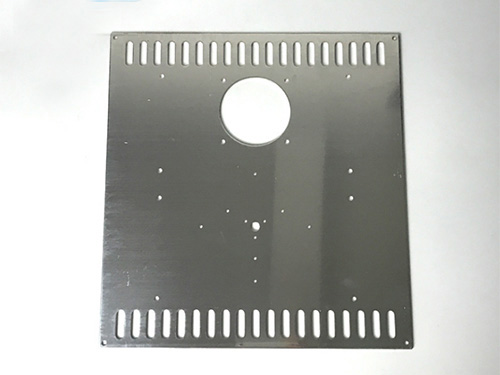

Chandelier housing

Chandelier housing

The shell of pendant lamp is a stamping part. The stamping part is a method of forming and processing...

-

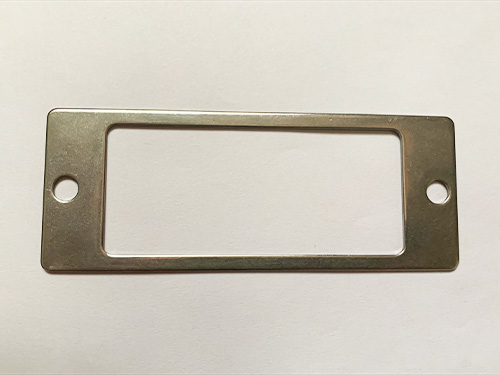

Stainless steel instrument hoop

Stainless steel instrument hoop

Stainless steel instrument hoop is stamping piece, stamping piece is by the press and die on the plat...

-

Stainless steel stamping parts

Stainless steel stamping parts

Stainless steel stamping parts are made of stainless steel material processing products, stainless st...

-

LED screen frame

LED screen frame

The frame of LED screen is a stamping part. The stamping part is a method of forming and processing p...

Hardware stamping parts should pay attention to maintenance after installation

Jul 24

2019

Stamping part is a forming and processing method that relies on press and die to exert external force on plate, strip, pipe and profile to produce plastic deformation or separation, so as to obtain the required shape and size of the workpiece (stamping part). Stamping and forging belong to the same plastic processing (or pressure stamping parts processing), collectively known as forging. The blank is mainly hot rolled and cold rolled steel plate and strip. Compared with castings and forgings, stamping parts are thin, even, light and strong. Stamping can produce workpieces with stiffeners, ribs, undulation or flanging that are difficult to produce by other methods to improve their rigidity. Due to the use of precision mold, the precision of the workpiece can reach micron level, and repeat high precision, consistent specifications, can punch out holes, boss, etc. Cold stamping parts generally no longer by cutting, or only a small amount of cutting. The precision and surface condition of hot stamping parts are lower than those of cold stamping parts, but they are still better than castings and forgings. Stamping is the production method, using compound die, especially multi-position progressive die, can complete multiple stamping process on a pressure machine, realize the automatic production from uncoiling, leveling, blanking to forming and finishing. High production efficiency, good working conditions, low production cost, generally every minute can produce hundreds of pieces.

Maintenance of metal stamping parts should pay attention to:

Metal stamping parts are parts processed by stamping, bending, stretching and other means. A general definition is - parts with the same thickness in the processing process. Metal stamping parts are widely used in various fields of our life, including some electronic devices, auto parts, decorative materials and so on.

Stamping equipment in addition to the thick plate forming with hydraulic press, generally use mechanical press. The automatic stamping production line with high productivity can be composed of conveying machinery, mould library and quick mould changing device, and controlled by computer program. Under the circumstance of producing dozens or hundreds of metal stamping pieces every minute, the working procedure such as material feeding, stamping, piece releasing and waste discharging can be completed within a short time.

Therefore, stamping production is a very important problem. General workpiece in the stamping process, due to the stamping process, especially in the cold forging stamping process, the temperature will rise quickly, add lubrication products lubrication, if not using lubrication and direct stamping, weld-assembly, surface parts without oil is convenient for welding and assembly.