-

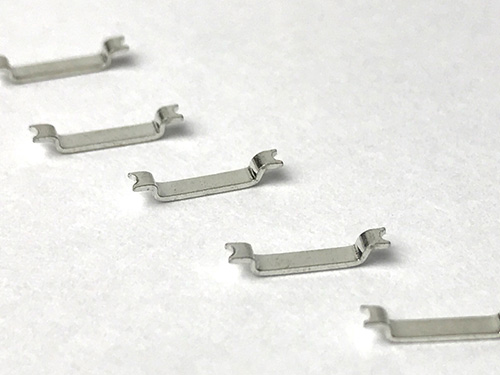

Jumper

Jumper

Jumper wire is stamping parts, hardware stamping parts hardness testing using rockwell hardness teste...

-

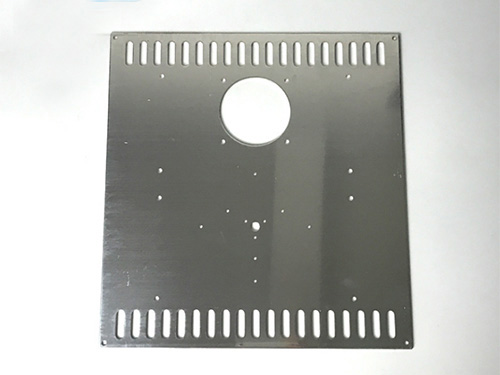

Chandelier housing

Chandelier housing

The shell of pendant lamp is a stamping part. The stamping part is a method of forming and processing...

-

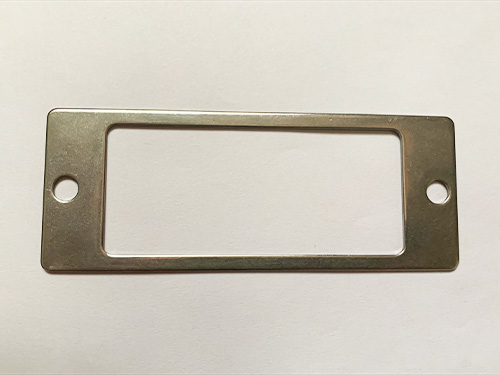

Stainless steel instrument hoop

Stainless steel instrument hoop

Stainless steel instrument hoop is stamping piece, stamping piece is by the press and die on the plat...

-

Stainless steel stamping parts

Stainless steel stamping parts

Stainless steel stamping parts are made of stainless steel material processing products, stainless st...

-

LED screen frame

LED screen frame

The frame of LED screen is a stamping part. The stamping part is a method of forming and processing p...

Drawing piece processing technology

Jul 24

2019

The production process of tensile parts refers to the whole process of making products from raw materials (or semi-finished products). For machine production, it includes the transportation and storage of raw materials, preparation of production, manufacture of raw materials, processing and heat treatment of parts, assembly and debugging of products, painting and packaging, etc. The content of production process is very extensive. Modern enterprises use the principles and methods of system engineering to organize production and guide production, and regard production process as a production system with input and output. Can make the management of the enterprise scientific, so that the enterprise has adaptability and competitiveness.

In the production process, the direct change of raw material (or blank) shape, size and performance, make it into a finished product process, known as the process. It is a major part of the production process. Such as blank casting, forging and welding; Heat treatment to change material properties; Parts of the mechanical processing, etc., are technological processes. A process consists of one or more sequential processes.

Many colleagues engaged in stamping and drawing parts processing have such understanding, why stamping and drawing parts processing will appear and wrinkle and crack? Here small make up for you to teach the processing technology of tensile pieces.

1. There are many reasons for the poor tensile parts. The profile quality of rolls, plates and molds will affect the quality of the final tensile parts.

2. If the mold is roughly cleaned and assembled, the situation of sharp damage will be increased. Therefore, the details should be fully considered at every juncture of the entire manufacturing process, even if quality problems are prohibited, affecting the final product profile.

3. The operation during the stretching process and the clamping and unloading of working equipment also have the general situation and quality of damaged parts.