-

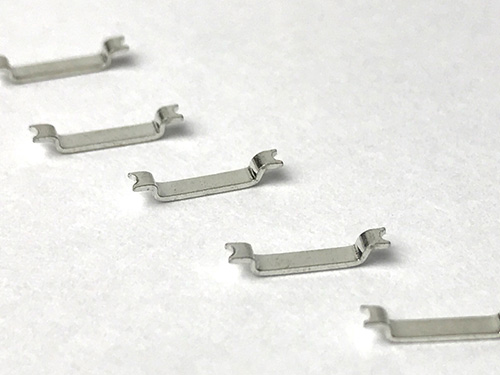

Jumper

Jumper

Jumper wire is stamping parts, hardware stamping parts hardness testing using rockwell hardness teste...

-

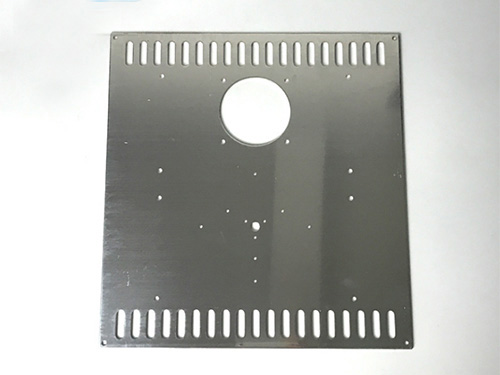

Chandelier housing

Chandelier housing

The shell of pendant lamp is a stamping part. The stamping part is a method of forming and processing...

-

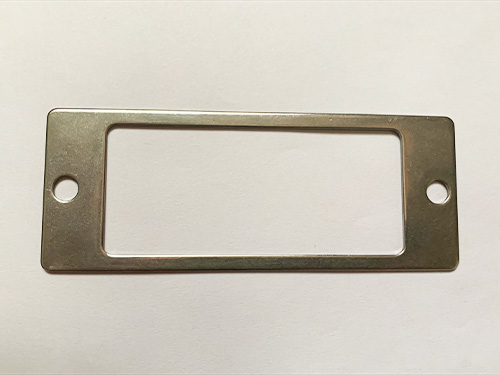

Stainless steel instrument hoop

Stainless steel instrument hoop

Stainless steel instrument hoop is stamping piece, stamping piece is by the press and die on the plat...

-

Stainless steel stamping parts

Stainless steel stamping parts

Stainless steel stamping parts are made of stainless steel material processing products, stainless st...

-

LED screen frame

LED screen frame

The frame of LED screen is a stamping part. The stamping part is a method of forming and processing p...

How are metal stamping parts made

Jul 24

2019

Metal stamping parts rely on the press and die on the plate, strip, pipe and profile, such as external force, make it produce plastic deformation or separation, so as to obtain the required shape and size of the workpiece (stamping parts) forming processing method. Metal stamping piece is in material consumption not big premise falls, through stamping manufacture comes out, its part weight is light, rigidity is good, and after sheet material passes plastic deformation, the organization structure of metal interior gets improvement, make stamping piece intensity rises somewhat. Stamping can produce workpieces with stiffeners, ribs, undulation or flanging that are difficult to manufacture by other methods to improve their rigidity. Hardware stamping parts using precision mold, workpiece precision can reach micron level, and repeat high precision, consistent specifications, can punch out holes, boss, etc.

Attention should be paid to the processing and production of stamping parts. In the use of the press or punching die and other tooling equipment, attention should be paid to ensure that the normal working state, to prevent the bar material can not feed along the correct positioning or can not press the gap feeding. To ensure the fastening of all parts of the die, pay attention not to let the various installation position of the die change, so as to avoid abrasions and compression of the workpiece surface and affect the quality of the workpiece surface. In the preparation of raw materials, to comply with technical provisions, pay attention to the measurement of raw material dimensional accuracy, strict inspection of raw material specifications and brand. Regular comprehensive inspection of stamping parts before production, to strengthen the inspection, to prevent accidents, prevent working parts and guide parts because of long-term operation and wear. Strictly abide by the matters that should be paid attention to when stamping parts are processed and produced, be careful and careful, in order to avoid causing no damage and loss.